The Popular Use of Aluminium Bronze in the Process of Metal Casting

Often manufacturers of metal objects cannot understand which metal alloy to pick for their metal casting requirements. There are lots of options that you can try. However, aluminium is probably the most popular one among all of them. This is why the demand for reliable and efficient Aluminium Bronze Casting Manufacturers is always high in the market.

Why Is Aluminium Bronze Casting Used?

Aluminium Bronze Casting is highly adaptable and flexible to the procedure of metal casting. This is why aluminium is a preferred choice in various industries, including oil, gas and airlines. The track record of success of this metal in a range of manufacturing and metal casting processes is quite impressive. This metal is easy to access and deal with during the procedure of casting to create big to small metal parts for various types of machinery.

What Is Aluminium Bronze?

The mixture of aluminium alloy and copper creates aluminium bronze. The grade or standard of this aluminium bronze is determined by the percentage of aluminium present in this product. This also determines how well the metal can take on a range of physical properties during the casting process.

When you cast bronze and aluminium together, the alloy becomes its best version and retains some features that make it irreplaceable.

- Immense strength to withstand extreme pressure and range of applications

- Reliable resistance against corrosion while used in oil, gas and airline industries

- The non-magnetic feature makes it ideal for industries where high-power magnets are used

- Non-sparking features make it perfect for various industries where sparks are not welcomed at all

A Perfect Metal to Withstand Wear and Tear during Casting

Metal casting is a process where the object has to pass through a lot of wear and tear. Flexibility, strength and adaptability are the key features that the metal must have to pass the procedure successfully. Aluminium bronze has it all. This is a unique metal that you can safely and efficiently repair and resize with welding when it is placed on a certain product.

These features make aluminium bronze a perfect addition to your casting project.

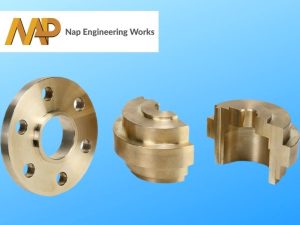

At NAP, we can deliver custom-designed aluminium bronze casting products. Our team is able to deal with various types of metal during the casting process to deliver products that our clients are looking for. This is why our clients rely upon and recommend us as an efficient Aluminium Bronze Casting Manufacturer in India.

Please get in touch with us for more details about our metal casting service.