Types of Lead Tin Bronze Materials that are Commonly Used

Tin Bronze is simply alloys containing 7 to 19% of tin which is considered a significant alloying element. Lead tin bronze casting is done by adding lead to the alloys. Manufacturers opine that as soon as the lead is added to tin bronze, the machinability and the pressure tightness increase. Lead is a good component that helps in reducing the tensile strength and flexibility of tin bronzes. Hence manufacturers prefer using lead as an option of casting the same on the tin bronze materials.

Now the question is, what type of leaded tin bronze should you use? A high leaded tin bronze, when used, contains high lead. On the other hand, normal leaded tin bronzes have low lead content. If the manufacturer uses high leaded tin bronze, then the anti-fiction properties of the alloy are highlighted more.

The majority of the companies use two significant types of leaded tin bronze, namely bearing bronze SAE 66, SAE 64, and Hi lead (C93900).

Here are some details about the different grades and their uses.

SAE 660

This bronze is also known as High leaded tin bearing bronze. This bronze is a common variant and has excellent machining properties, and is challenging. A manufacturer generally selects this alloy for its ability to resist wear and tear. Moreover, they’ve anti-fictional qualities, which are helpful for production purposes. Majorly this alloy is used for industrial purposes. You can find this alloy in the bushings of electric motors, cranes, track rollers, and valves. Since the alloy is challenging, hence it is ideal for industrial production purposes. It can be machined, broached, and reamed seamlessly without any problems.

SAE 64

In mechanical and industrial terms, this metal is commonly known as the 80-10-10 bronze. It has got its unique name from its chemical composition. It comprises 80% of copper, 10% of tin, and 10% of lead. Hence the name is entirely justified. As soon as the lead is added, the fun fact is added, the metal becomes lubricant in nature. Although you may not see it in products of your daily use, however, the industrial manufacturers know the valuation. It is used for steer knuckle bushings, rolling mill, valve rocker, and Trunnion bearings. Like the other variant mentioned above, this is also wear-resistant and highly durable. Hence you can use it under heavy pressure, shocks and vibrations without causing any harm.

Hi lead-bearing bronze

For products or applications where regular lubrication doesn’t occur, this metal is valuable. In applications where high speed and moderate pressures are required, this is a valuable metal. Hi lead-bearing bronze has an excellent anti frictional property and is highly resistant to corrosion. You’ll find the same being used in diesel engine bearings, rolling mill bearings, seals and bushings for gas pumps, etc.

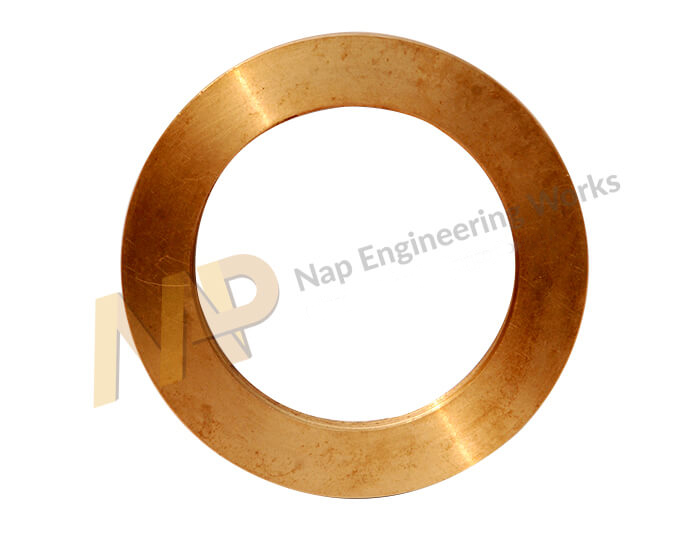

At NAP Engineering Works, you’’ get the best quality leaded tin bronze castings for all types of industrial product manufacturing purposes. Customer satisfaction y prioritizing quality is our primary motto; hence contact us for more details on different metals.